Advanced Semiconductor Manufacturing Insights: Explore Trends, Challenges, and Expert Advice

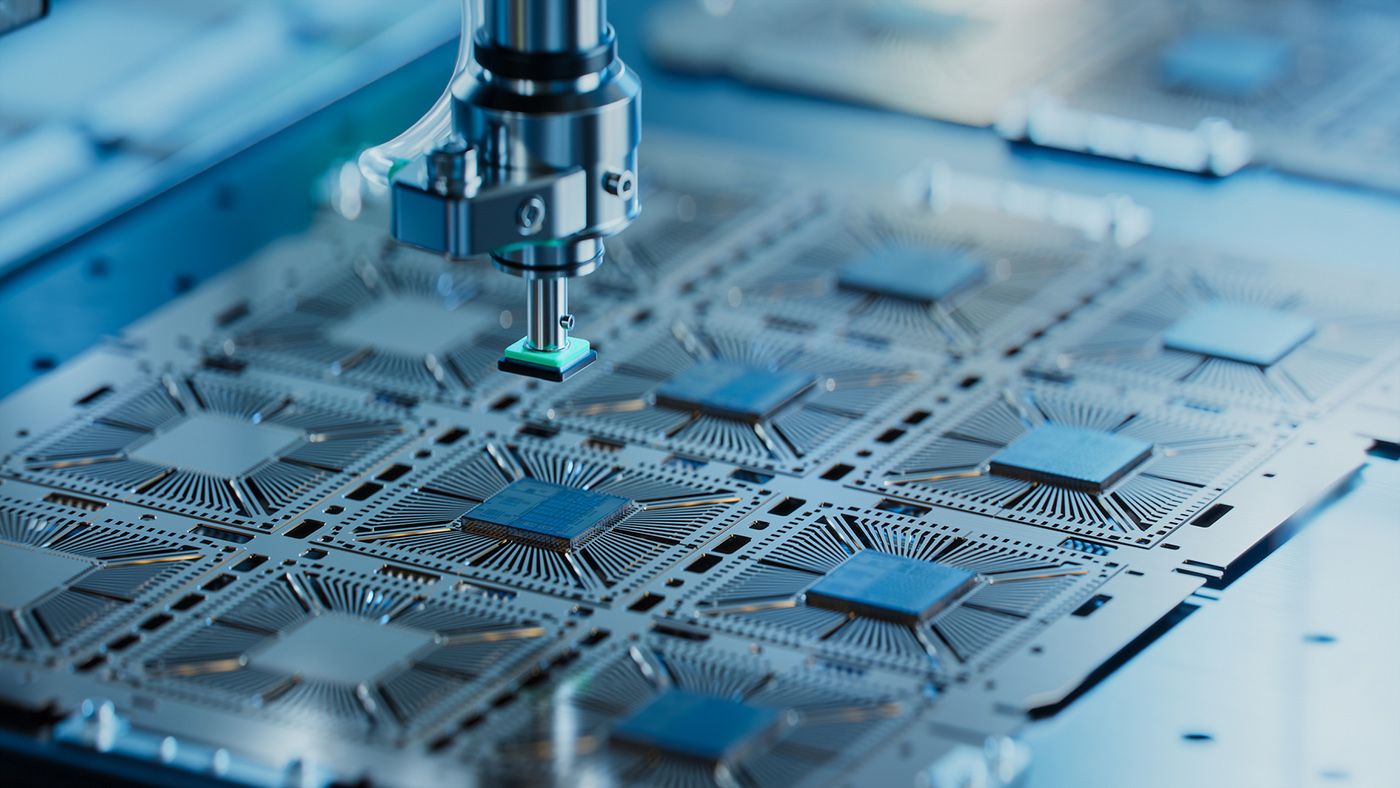

Advanced semiconductor manufacturing refers to the processes by which microchips (semiconductors) are designed, fabricated, packaged, and tested at extremely fine scales. These chips power everything from smartphones and cars to data centers and artificial intelligence systems. The need for such sophisticated manufacturing arises because modern technology demands ever-smaller, faster, and more energy-efficient chips.

As transistor sizes continue to shrink—moving toward 2 nm and 3 nm generations—and packaging becomes more complex through chiplets and 3D stacking, the manufacturing process requires greater precision, specialized materials, and advanced technologies. In short, semiconductor manufacturing exists because modern electronics and computing depend on ultra-dense, high-performance chips that can only be made with advanced production methods.

Importance

Advanced semiconductor manufacturing matters because semiconductors are the foundation of nearly every modern industry. These chips are essential in sectors like automotive, telecommunications (5G/6G), cloud computing, artificial intelligence (AI), the Internet of Things (IoT), defense, and consumer electronics.

Without continuous improvement in manufacturing processes, these systems could not meet the increasing demands for speed, energy efficiency, and reliability. Governments, businesses, and consumers all benefit from advancements in semiconductor technology. Governments view chip production as a strategic priority for economic and national security reasons, while businesses rely on advanced chips to power innovation.

Below is a summary of why this field is crucial:

| Area | Why Advanced Manufacturing Matters |

|---|---|

| Performance & efficiency | Smaller nodes and new materials (like silicon carbide and gallium nitride) increase speed and reduce power use. |

| Supply-chain resilience | Localized chip fabrication reduces dependence on a few global suppliers. |

| Innovation enablement | Enables emerging technologies like AI, autonomous vehicles, and IoT sensors. |

| Global competitiveness | Semiconductor production capacity determines national economic strength. |

Advanced semiconductor manufacturing is not merely about creating chips—it underpins global innovation and economic stability.

Recent Updates

The past year has seen major changes in how semiconductor manufacturing is advancing worldwide:

-

The global semiconductor market is projected to reach nearly $700 billion in 2025, growing around 11 percent from the previous year.

-

Growth is now driven by AI and data-center demand rather than traditional consumer electronics.

-

AI processors, smart manufacturing, and energy-efficient designs are dominating new chip developments.

-

Manufacturers are increasingly using digital twins, IoT sensors, and predictive maintenance to optimize production.

-

New materials like silicon carbide (SiC) and gallium nitride (GaN) are enabling better performance and thermal efficiency.

-

Workforce shortages remain a key issue, as fabs require highly skilled engineers and technicians.

-

Many nations are investing heavily in domestic fabrication plants to reduce global dependency and strengthen supply-chain resilience.

A quick look at global chip sales shows this growth trend:

| Year | Estimated Global Chip Sales (US$ Billion) |

|---|---|

| 2024 | ~627 |

| 2025 | ~697 |

The semiconductor manufacturing industry is currently balancing tremendous opportunity—through growth and innovation—with challenges like complexity, resource needs, and supply-chain management.

Laws or Policies

Government policies and programs play a major role in shaping the semiconductor manufacturing landscape. Given the high investment costs and strategic importance of this industry, most countries have introduced specialized programs to support domestic chip fabrication.

In India, the India Semiconductor Mission (ISM), launched under the Ministry of Electronics and Information Technology, aims to strengthen the semiconductor ecosystem. With an outlay of ₹ 76,000 crore, the program offers:

-

Fiscal support for setting up semiconductor wafer fabs and display fabs

-

Incentives for assembly, testing, and packaging facilities

-

Design-linked incentives to encourage R&D and innovation

The ISM seeks to make India a global hub for semiconductor manufacturing by supporting technology transfer, collaboration, and local ecosystem development. Several Indian states have also introduced complementary semiconductor policies to attract investment and create skilled talent pipelines.

Globally, similar initiatives exist—such as the U.S. CHIPS and Science Act, European Chips Act, and Japan’s Semiconductor Support Program—which provide financial incentives, tax credits, and R&D funding to increase domestic manufacturing capacity.

These policies directly influence where factories are built, what technologies are adopted, and how international partnerships are structured. They also play a crucial role in addressing export regulations, intellectual property protection, and trade dependencies.

Tools and Resources

Understanding semiconductor manufacturing requires both technical and practical resources. The following are useful tools and references for students, professionals, and researchers:

-

Industry Reports: Global semiconductor outlooks published by technology research firms provide valuable data on market projections, innovation areas, and industry trends.

-

Forecast Databases: Organizations such as trade associations and statistical groups publish quarterly semiconductor sales and growth forecasts.

-

Government Resources: Websites for national semiconductor programs provide updates on policies, subsidies, and partnership opportunities.

-

Technology Blogs and Portals: Corporate technology platforms and think-tank publications share articles on upcoming trends like chiplet integration, AI chips, and 3D packaging.

-

Research Papers: Technical papers cover topics like defect detection using AI, yield optimization, and advanced lithography techniques.

-

Factory Simulation and Modeling Tools: Digital twin software, process simulators, and yield modeling systems are widely used in fab management.

-

EDA and Design Tools: Electronic Design Automation (EDA) software supports chip layout, verification, and manufacturability analysis.

-

Industry Conferences: Events like SEMICON Taiwan and other semiconductor expos showcase global advancements and manufacturing innovations.

These resources are helpful for anyone seeking a deeper understanding of how the semiconductor industry evolves technically and strategically.

FAQs

Q1: What does “advanced node” mean in semiconductor manufacturing?

An “advanced node” refers to a chip production process that uses extremely small transistors—often 3 nm or 2 nm. Smaller nodes increase transistor density, reduce energy consumption, and improve chip performance.

Q2: Why is semiconductor manufacturing so complex and expensive?

The process involves building chips layer by layer using nanometer-scale precision in clean-room environments. It requires highly specialized tools, materials, and expertise. Additionally, each new generation of chips demands new fabrication technologies and higher R&D investments.

Q3: What are the major challenges in semiconductor manufacturing today?

Key challenges include:

-

Shortages of skilled talent across engineering and operations

-

Global supply-chain dependencies on materials and tools

-

Energy consumption and environmental sustainability concerns

-

Managing defect rates and yield at smaller geometries

-

The need for advanced packaging and heterogeneous integration

Q4: How does chip packaging affect manufacturing?

Packaging determines how the chip interfaces with the external world. Advanced packaging techniques such as chiplets, 3D stacking, and wafer-level integration enhance performance, thermal efficiency, and miniaturization.

Q5: How do government policies impact semiconductor manufacturing?

Policies shape investment incentives, taxation, and location decisions for fabrication plants. They influence technology adoption, R&D funding, and international trade relationships. Supportive policies can accelerate domestic manufacturing growth and global competitiveness.

Conclusion

Advanced semiconductor manufacturing represents the backbone of modern technology. Every new wave of innovation—from AI and electric vehicles to quantum computing—depends on the ability to produce chips that are faster, smaller, and more efficient.

As the world becomes increasingly digital, nations and industries are recognizing semiconductor manufacturing as a strategic priority. The industry’s progress is now driven by a combination of scientific innovation, government policy, sustainability goals, and skilled talent development.

Understanding the dynamics of this field—its context, current developments, policies, and tools—helps anyone interested in technology appreciate how the most complex objects ever made by humans are shaping the future of computing, communication, and connectivity.